Chop-Check pumps are designed to move medium-to-high viscosity fluids in difficult applications.

The heavy-hitters of the line, ARO® chop-check pumps are designedto move medium-to high- viscosity fluids ranging from 15,000 cPs to more than 1,000,000 cPs, and at delivery rates up to 12.2 gpm (46.3 L/min).

The heavy-hitters of the line, ARO® chop-check pumps are designedto move medium-to high- viscosity fluids ranging from 15,000 cPs to more than 1,000,000 cPs, and at delivery rates up to 12.2 gpm (46.3 L/min).

Applications advantages of Chop-Check:

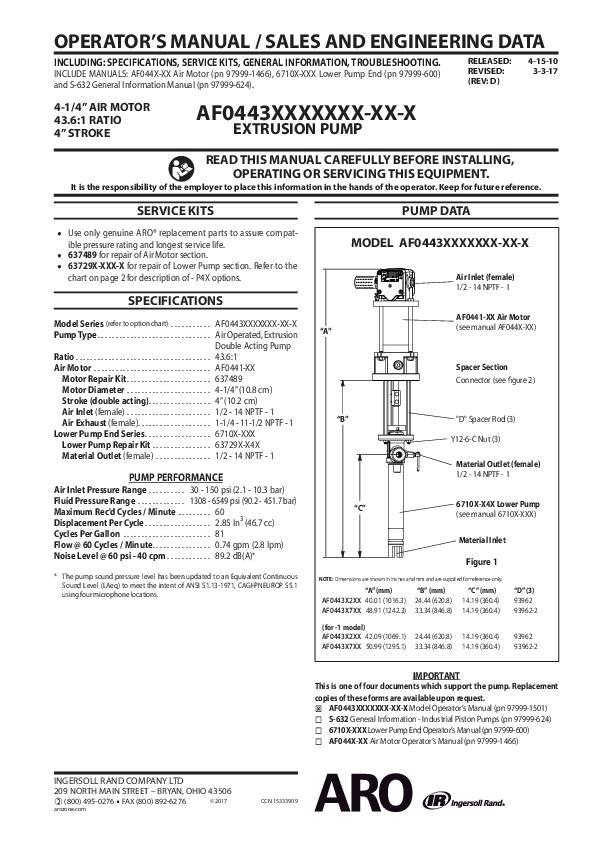

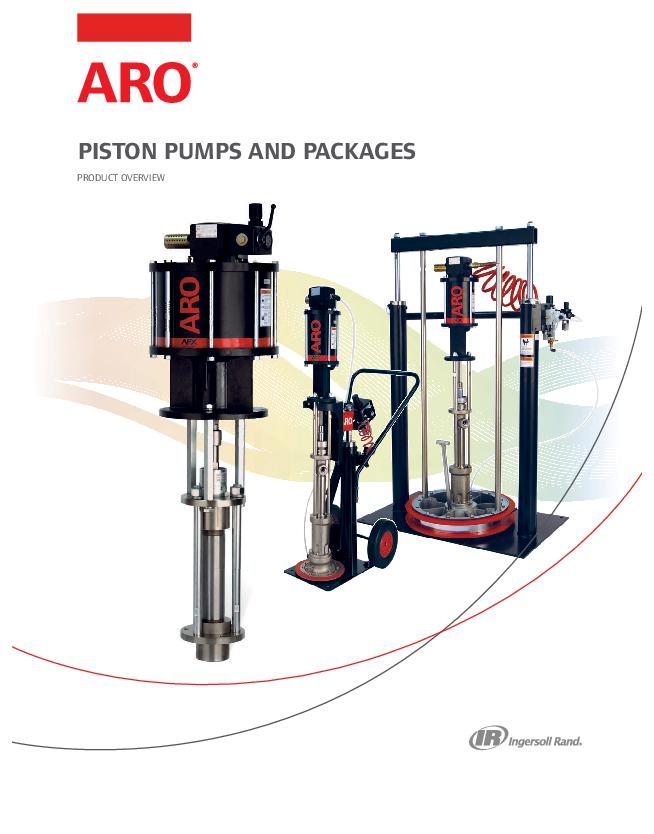

Extrusion: Chop-Check pumps are workhorses – able to deliver viscous adhesives, sealants, caulking and heavy lubricants to the application point at the desired pressure and flow rate.

Transfer & Supply: Depending on the model, some Chop-Check pumps are capable of achieving flow rates up to 12.2 gpm, ensuring efficient transfer of heavy greases, inks and other viscous materials.

Materials advantages of Chop-Checks:

Chop-Check pumps have a primer piston to ‘feed’ material into the pump. They are often used in conjunction with a follower plate to force material down. This prevents loss of prime due to Channeling – a condition where the pump inlet becomes surrounded by air due to the cavity formed when a high viscosity material does not level off when removed (Slumpability).

- Stringy materials: Chop-Checks have mechanical, flat checks to overcome materials that resist cut-off and adhere to themselves.

- Tacky materials: Chop-Check pump options come in high ratios to generate the fluid pressure needed to move materials that will adhere to hoses and equipment while wet.