Chemical compounds can be vital to industrial and manufacturing production. But they also can be harmful to your staff, the environment and your productivity if not handled properly.

Whether you’re filling a tank, drum or bucket — or dosing chemicals in precise amounts — ARO offers a variety of pumping systems. Our chemical pumps are designed to ensure the safety and integrity of your speci

Whether you’re filling a tank, drum or bucket — or dosing chemicals in precise amounts — ARO offers a variety of pumping systems. Our chemical pumps are designed to ensure the safety and integrity of your speci

fic application.

Our pumps are expertly engineered to meet the challenges of chemical processing, including:

- Moving a wide range of viscosities, from thin fluids to thick, slower-moving substances

- Bulk fluid or chemical transfer, including tanker or railcar unloading

- Chemical injection pump, chemical dosing pump or chemical metering pump needs

- Filter press operations (the separation of solids and liquids using large-scale pressure filtration)

- Transferring or draining harsh chemicals, such as hydrochloric acid, ferric chloride or sodium hypochlorite

- Dosing or mixing active ingredients to create specific products, such as detergents, household chemical cleaners or paints

- Measuring and dispensing chemicals within metered water treatment systems

- Circulation of chemical treatment baths

- Transferring seed coating solutions or fertilizers used in agriculture

ARO industrial chemical pumps can withstand aggressive, corrosive, flammable or potentially explosive fluids. We offer a variety of corrosion-resistant materials — metallic and non-metallic — for the safest fluid handling in chemical processing. We manufacture high-quality chemical pumps and systems for some of the largest industrial and manufacturing applications all over the world.

The ARO Difference

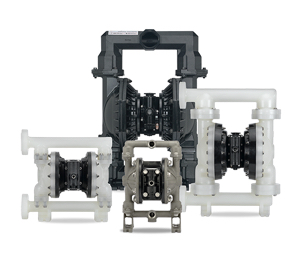

ARO air operated double diaphragm pumps are a reliable, cost effective choice for the chemical industry.

ARO AODD pumps are expertly engineered to handle most chemicals, including acids, bases, caustics and solvents. Our positive displacement pumps are designed to prevent leaks and cross contamination.