Mục lục bài viết

Available in 1″ and 2″ Ports

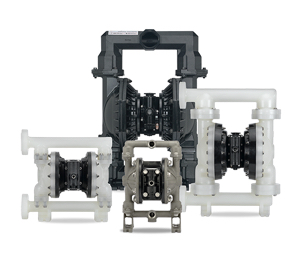

The latest addition to the ARO® portfolio offers a conductive polyvinylidene fluoride (PVDF) wetted part driven by the advanced EXP pneumatic motor technology.

Available in 1-inch and 2-inch port sizes, the new Conductive PVDF Pump complements the existing range of ARO® process pumps. It offers the lowest downtime and lowest cost of ownership in highly critical applications, which include handling corrosive chemicals in hazardous duty environments.

PVDF is well suited for a variety of industries and applications, including:*

- Chemical injections to treat wood or pulp in paper production

- Chemical dosing or slurry draining in wastewater treatment

- Transfer and delivery of acids to etch solar panels

- Transfer and flushing of pigments, inks or solvents

- Collecting agrochemical byproducts

- Loading or unloading petrochemicals from trucks and other large containers

- Transferring additives or chemicals in manufacturing fertilizer, detergent, pharmaceuticals or personal care products

- Chemical injections to treat wood or pulp in paper production

- Chemical dosing or slurry draining in wastewater treatment

- Transfer and delivery of acids to etch solar panels

- Transfer and flushing of pigments, inks or solventsCollecting agrochemical byproducts

- Loading or unloading petrochemicals from trucks and other large containers

- Transferring additives or chemicals in manufacturing fertilizer, detergent, pharmaceuticals or personal care products

1” EXP Non-Metallic Air Operated Diaphragm Pump

Learn More

2” EXP Non-Metallic Air Operated Diaphragm Pump

Learn More

Available in 1″ and 2″ Ports

The latest addition to the ARO® portfolio offers a conductive polyvinylidene fluoride (PVDF) wetted part driven by the advanced EXP pneumatic motor technology.

Available in 1-inch and 2-inch port sizes, the new Conductive PVDF Pump complements the existing range of ARO® process pumps. It offers the lowest downtime and lowest cost of ownership in highly critical applications, which include handling corrosive chemicals in hazardous duty environments.

PVDF is well suited for a variety of industries and applications, including:*