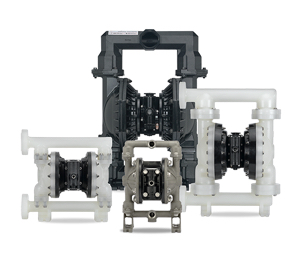

Simply Versatile

2-ball pumps are among the most versatile in the ARO® line. They are capable of handling applications from simple transfer to the extrusion of low- to medium- viscosity materials up to 100,000 centipoise (cPs) with fluiddelivery up to 18.1 gpm (68.6 L/min).

Applications advantages of 2-balls:

- Spray: 2-ball pumps deliver the constant flow rate and pressure needed for consistent and efficient coatings applications

- Transfer & Supply: Depending on the model, some 2-ball pumps can achieve flow rates up to 18.1 gpm, providing dependable results

- Extrusion: 2-ball pumps generate pressure to handle extrusion of low-to medium-viscosity

- Lubrication: ARO® 2-balls pumps provide the flow and pressure required for moving light oils and grease lubricants

- High Pressure Cleaning: ARO® Wash Pump Packages are portable and offer the the right option for industrial cleaning applications

Materials advantages of 2-balls:

- Sheer sensitive materials: ARO® 2-ball pumps minimize friction points to prevent fluid shear, when compared to other similar pumping technologies

- Abrasive and high solid materials: ARO 2-ball pump minimize friction points and allow smooth passages to maintain fluid consistency

- Optional ceramic coating provides an even

stronger defense against highly abrasive fluids like paint and glass-filled sealer