Tired of troubleshooting your progressive cavity pumps?

AODD pumps can overcome many common progressive cavity pump disadvantages.

Progressive cavity pumps are used in a wide variety of applications and industries. These pumps are designed for tough working conditions and to resist high temperatures.

Unfortunately, due to the constant strain these pumps tolerate and the overall wear they suffer, progressive cavity pumps require frequent maintenance, repair, and replacement parts. Lack of maintenance or misapplication can result in expensive repairs or replacement.

Common Progressive Cavity Pump Disadvantages

Running dry will quickly destroy expensive stators and rotors. The interference fit between the rotor and stator requires the fluid being pumped to lubricate the contacting surfaces. Running the pump dry is the most common cause of failure in cavity pumps.

Additional progressive cavity pump issues include:

- Frequently replacing stators due to abrasive fluids

- Low viscosity fluids slipping by the rotor to the stator, making the pump less efficient

- Running dry for less than a minute will destroy the stator

- Expensive maintenance and parts

- Typical requires maintenance at least two people and 4-6 hours

- Shaft alignment is difficult to maintain due to constant pump vibration, which commonly leads to shaft seal failures

- Deadhead or stall can cause severe damage to the pump or system

- Any pump failure may contaminate the product

- Complex pump selection process

Air Operated Diaphragm Pumps easily handle processes where fluid contains abrasives or could run dry.

Contact Us

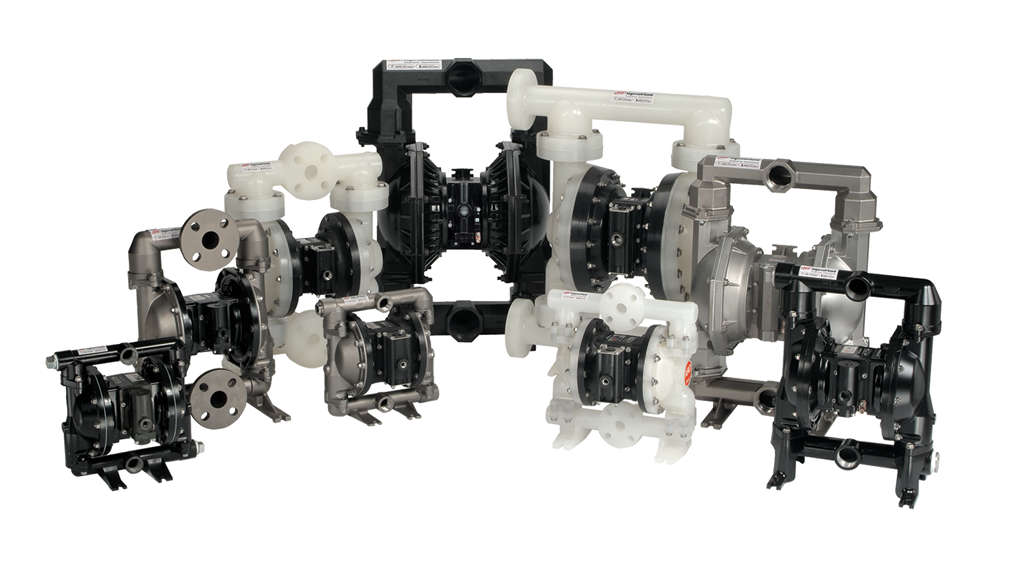

ARO® AODD Pump Advantages

ARO® air operated diaphragm pumps can easily handle processes where fluids contain abrasives or could run dry.

Additionally, all ARO® EXP Series pumps are Process Ready. As a standard feature, each EXP Series pump comes with connection points that provide a communication portal from your pump for process monitoring and control. Whether you have the need today or are planning to expand your capabilities in the future, ARO® has the right solution to improve your connection to your process and maintenance system.

Maintenance for an ARO® air operated diaphragm pump is simple, fast, and inexpensive when compared to progressive cavity pumps.

AODD pump advantages also include:

- Ability to run dry

- Easily pump a wide range of fluids, including high viscosity and abrasives in suspension

- Lower maintenance costs in both time and materials

- No dynamic seals to leak or maintain

- Broad chemical compatibility

- Smaller footprint, size and weight