Mục lục bài viết

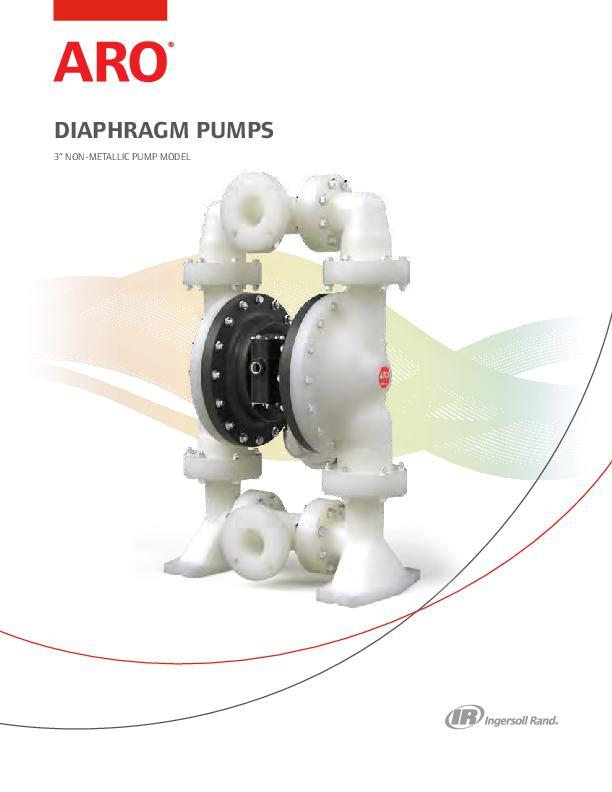

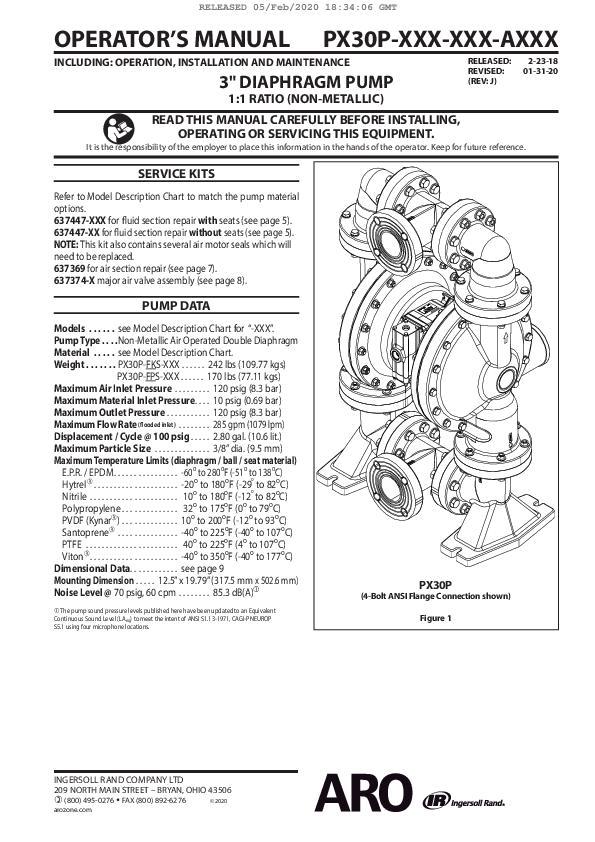

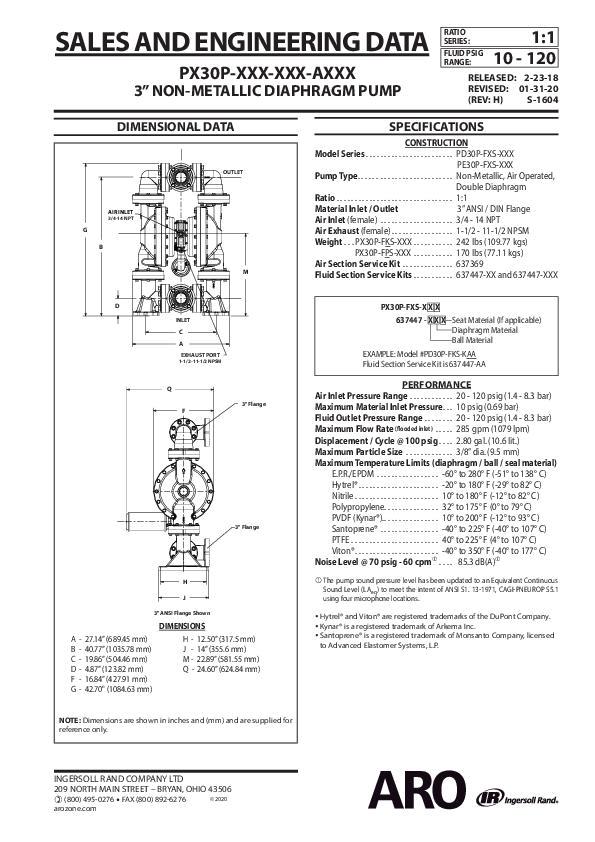

ARO EXP Series diaphragm pumps now include new 3” non-metallic models available in polypropylene or PVDF. The NEW 3” non-metallic models are reliable, efficient and offer a lower Total Cost of Ownership that has made ARO a leading brand in the pumping industry. With flow rates up to 285 gpm (1,079 lpm) our 3” non-metallic models can meet or exceed your application requirements.

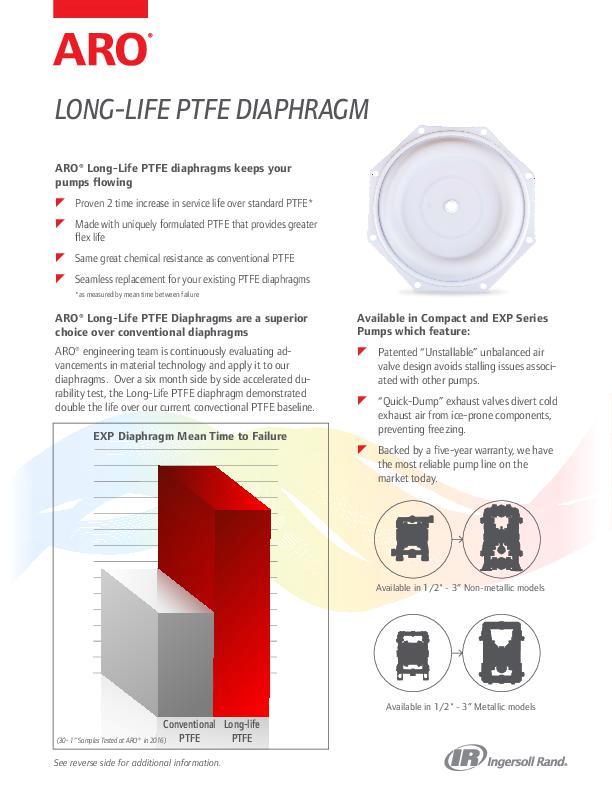

Long-Life PTFE Diaphragms also available.

3″ Non-Metallic Pump Features

- Efficient transfer leveraging EXP air motor design

- Faster transfer, 55% more flow than ARO EXP 2” Non-Metallic models

EXP Features

- EXP Total Cost of Ownership (TCO) Best TCO of all major competitive models tested

- EXP Reliability Lube free patented differential valve both on major air valve and SimulShift (Pilot Valve) provides reliable worry free operation

- EXP Serviceability Modular construction, reduced parts count and simple to use repair kits will minimize repair time and cost

- EXP Control & Monitoring – “Process Ready” Electronic interface capability assures consistent flow rates and pinpoint control. End of stroke feedback (EOS) and leak detection.

- EXP Productivity Maximized flow rates with minimized pulsation and air consumption = Maximum Performance

Accessories

- 66109 – Air Line Connection Kit: contains Piggyback Filter / Regulator, pipe nipple & 5’ section of hose

- 637369 – Air Motor Service Kit

- 6373447-AA, 637447-GG, 637447-TL, 637447-TT – Fluid Section Service Repair Kit

- End of Stroke Sensors: 97121 – Regular Duty

- Leak Detection: 67237 – Regular Duty

Pump Casing Materials

- PVDF

- Polypropylene

Diaphragm Materials

- LongLife PTFE

- Santoprene®

- Hytrel®

- Buna-N

- PTFE w/ Santoprene ® backer