Peristaltic Pumps

A reliable and simple solution for dispensing, dosing, metering and transferring a wide variety of fluids

Contact Us

Request a Quote

Request Service, Parts or Support

Find Dealers

Peristaltic pumps — also known as hose pumps or tube pumps — provide a reliable and simple solution for moving almost any fluid in a wide variety of markets and applications.

Peristaltic hose pumps and peristaltic tube pumps can transfer, dose or meter a range of fluids, including cosmetic lotions, abrasive slurry or sodium hypochlorite.

Peristaltic pumps offer a flexible solution for chemical processing, wastewater applications, food & beverage and more. When paired with variable speed drives, pump flow can be adjusted to accurately meter or dose fluids.

At the core of the pump is an elastomeric hose or tube that contains the fluid, virtually eliminating the possibility of product contamination. A wide variety of tube or hose materials are available to meet the chemical compatibility required for each application.

Peristaltic pumps are designed to run dry, self-prime and offer a high suction lift (32 ft / 9.8 m). Their seal-less construction uses no mechanical seals or stuffing boxes, which can lead to fluid leaks.

Peristaltic pumps are easy to setup, operate and maintain without specialized training. These pumps do not require compressed air or rely on valves that can clog. The peristaltic pumping motion is ideal for handling abrasive fluids and shear sensitive fluids.

At ARO, we want to help our customers determine the best pump for their job and application.Albin Pump has 30 years of experience in peristaltic technology.ARO is proud to have the Albin brand as an extension of our pump offering.Albin brings expertise in the peristaltic pump technology to the ARO knowledge and team you have trusted for 90 years.

To learn more about peristaltic pumps, please visit www.albinpump.fr.

Two shoes mounted at 180-degrees on a rotor alternately compress a reinforced rubber hose that contains a fluid to be pumped. The compression of the hose by the rotating shoes creates continuous suction at the inlet of the pump and pushes the fluid to the outlet of the pump. The pump casing contains a lubricant that reduces friction and ensures the best pump performance with a minimum of maintenance. The pumped fluid is in contact only with the interior of the rubber hose, thus permitting the pumping of a wide variety of reactive fluids.

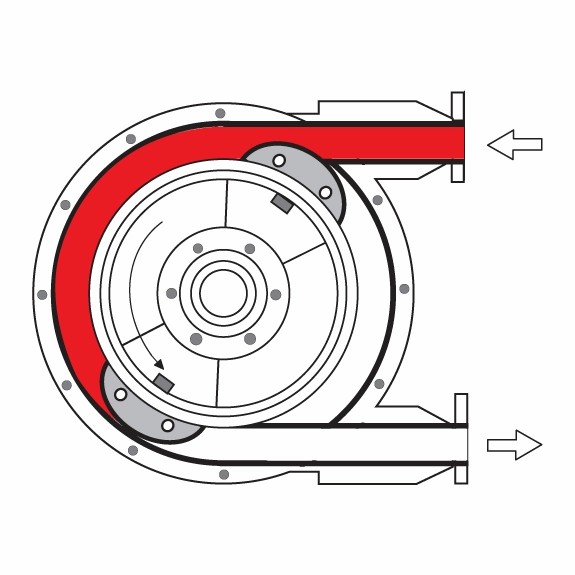

Phase 1

The pump hose is compressed successively by two pressing shoes assembled on a rotating wheel. The first shoe, by pressing the walls of the hose, will create a vacuum and attract the pumped liquid into the hose.

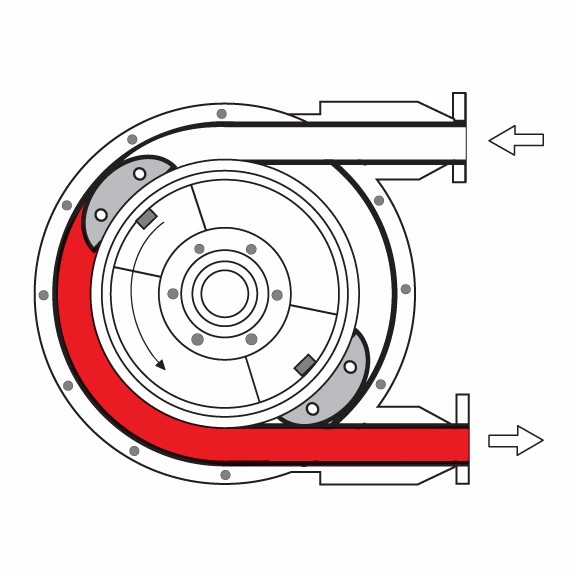

Phase 2

The pumped liquid has now entered the hose. The second shoes will compress the hose and push the liquid toward the pump outlet.

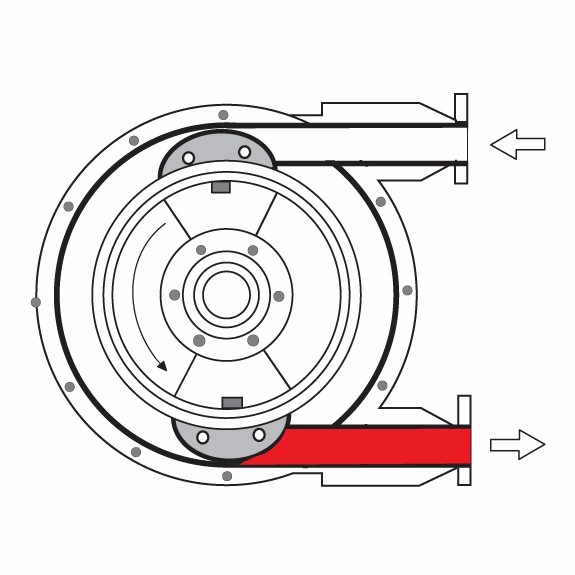

Phase 3

When the shoe at the discharge side is detached from the hose, the other shoe diametrically opposite is already in compression, thus avoiding an internal product reversal. The pumped fluid is then successfully pulled in and pushed out due to the wheel rotation.

Municipal

Water and Waste Water