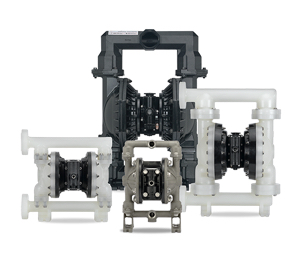

ARO compact diaphragm pumps feature flow rates up to 33 GPM (125 LPM) and offer a wide range of material and porting configurations. EXP Series pumps are available with Electronic Interface capability, solenoid actuation for accurate cycle rate control, and long-life PTFE diaphragms, providing a 2-time increase in service life over standard PTFE*.

Applicable Industries

Adhesives & Sealants

When you need a quality seal or precise, consistent adhesive dispensing system, count on ARO for your application.

Chemical Processing

When your process requires the use of acids, caustics, solvents and other hazardous chemicals, we know that safety comes first.

General Manufacturing

Our comprehensive range of industrial pumps offer consistent fluid transfer for a wide variety of fluids with solids content.

Cosmetics & Pharmaceuticals

ARO Pump solutions for the cosmetic industry and pump solutions for the pharmaceutical industry are built to minimize leaks and maximize lifespans.

Printing

Our range of compact pumps are designed for performance and reliability in the printing industry.

Water &

Wastewater

Our water and wastewater pumps deliver strong performance with longer lifespans, all at a lower cost.